| Sign In | Join Free | My udpf.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My udpf.com |

|

Type : Multi-Function Packaging Machine

Condition : New

Function : Filling, Wrapping, Sealing

Application : Beverage, Food, Medical

Packaging Type : Bags, Film, Pouch

Packaging Material : Plastic, Paper

Automatic Grade : Automatic

Driven Type : Pneumatic

Voltage : 220V,50/60HZ

Power : 2.2Kw

Place of Origin : Guangdong, China (Mainland)

Brand Name : UMEO

Dimension(L*W*H) : L1150*W960*H1780mm

Certification : CE Certification

Product name : vertical form fill seal packing machine

Main Function : Weighing Forming Filling and Sealing

Packing material : Complext filme,such as OPP/CPP

Bag type : Four-side sealing ,stick bag,pillow bag

Speed : 30-80 bag /min

Film Width : 320mm

Film thickness : 0.05-0.1mm

Control system : servo+touch screen

Bag length : 50-200mm

Bag width : 50-150mm

After-sales Service Provided : Engineers available to service machinery overseas

Selling Units : Single item

Single volume : 3 cm 3

Single gross weight : 380.0 kg

Package Type : inner wrap with PE film,external with plywood case

MOQ : 1 Sets

Price : US $5600.00

Vertical form fill seal packing machine

Feature

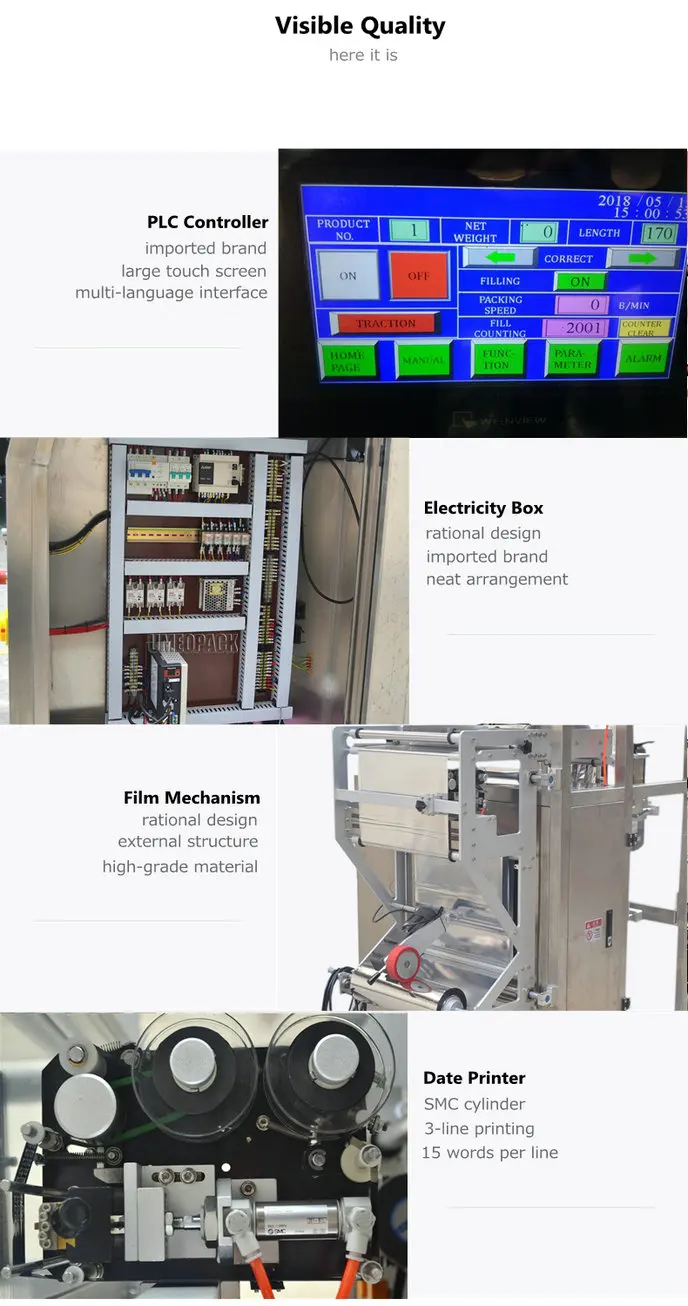

1. Imported PLC computer control system,color touch screen,easy operation and much more stable;

2. Seperate pneumatic control and power control with low noise and more stable circuit ;

3. Imported servo pulling film system and imported color sensor,accurate positioning,perfect operation;

4. Multiple automatic alarm protection,reducing the loss furthest;

5. External loading film system to make the setting easily.

6. Enclosed mechanism is used to prevent dust entering effectively.

Specification

Application

vertical form fill seal machine can pack different product with different measuring device.

UMEO always pays much more attention to every part of each packing machine

Pre-sales Services:

Step 1: One on one free project consulation,designing and free cost evaluation.

Step 2: Production line recommendation.

Step 3: Order confirmed.

Medium-sales Services:

Step 4: Deposit in and machine production on.

Step 5: Qualified raw material suppliers ( fabric,solutions,films,stickers etc) introduced.

Step 6: Raw material sample purchased for trial running.

Step 7: Machine inspection,installation and operation training conducted.

Step 8: Wipes production experience provides.

Step 9: Machine settled for standard plywood case packaging.

Step10:Balance received and delivery machine.

After-sales Services:

Step11: Machine transportation.

Step12: Long-distance guidance for installation and operation or engineer available for oversea.

Step13: Life-long machine maintenance service and warranty.

|

|

Vertical form fill seal bag packing machine with heat sealer Images |